How does electrical power work in a car?

Is the basics of electricity in a car or motorcycle already clear to you? Then just scroll through to the heading 'Voltage loss in the electrical circuit of your car'.

To make clear what transition resistance is in an electrical circuit, I will first explain the basics of electrical current in a car. Let's take the headlight unit as an example. The headlight unit contains a bulb. On the PLUS connection of the bulb we put a wire that with some detours, like through your fusebox and the light switch, arrives at the PLUS pole of the voltage source. In our case that voltage source is the battery or the dynamo when the engine is running.

On the MIN terminal of the bulb we put a wire that eventually arrives at the MIN pole of your battery. In the case of a vehicle such as a car, motorcycle, moped or tractor, the metal of the body and engine is used to conduct the return current to the MIN pole of the battery. This is a smart solution because it requires much less copper wire to conduct the current. I will explain this below.

The body of the car as a conductor of electric current (ground)

Eventually all the current after a consumer, also called load, goes back to the MIN pole of the battery. So why not make one wire that brings all the current back together. In fact, that's what they did and it simply uses the bodywork for that.

This is a solid piece of metal that conducts the current perfectly and no cable can compete with it. This saves a lot of copper wire, and thus costs, because you no longer have to run a wire from every electrical component all the way back to the battery. You can simply run a short wire from the MIN side of the consumer to the body. Then, close to the battery, you run a thick wire from the body to the MIN terminal.

Such a connection to the body is called a ground connection. The short section from the body to the MIN pole of the battery is a main conductor and is therefore equipped with an extra thick cable. This is where all currents come together.

In the picture you see an example of how the battery MIN pole is connected to the body of the car with a thick 25 mm² mains cable. In this case with a yellow / green cable, other colors are also used such as gray or brown.

Electrical components without MIN wire

In really old classics, there were no ground wires drawn at all. Not even short pieces of wire from the MIN connection of a component, such as a light, to a ground point on the body. There, all electrical components made direct contact with their metal housing (the MIN). Nowadays usually ground wires are used everywhere. Sometimes the current had to pass through all kinds of hinges and metal plates and bolts before it reached the solid body. In practice this often resulted in blinking or failing lights after a while.

In modern cars and youngtimers we still have some components without a ground / minus wire. You see this a lot with components on the engine. Think about sensors like the coolant temperature sensor or the oil pressure sensor. Only one wire is connected to these sensors. That is the plus wire. The current flows through the sensor and via the casing of the sensor through the engine block back to the MIN pole of the battery.

Battery cables / main power cables

The body is of course big enough to handle heavy currents. But as you read above, the connection from the body and engine block to the MIN pole of the battery is still met with a thick cable. In these cables all currents come together and that is why we call it a mains cable. We usually call them battery cables because they are directly connected to the battery. They are also called welding cables.

It is the same in nature. A main river, to which all small rivers flow, is wide. You can't suddenly make it very narrow. You would get too much friction and the whole thing would overflow. A thin wire as a main conductor would give too much resistance, causing it to lose a lot of voltage and to heat up and wear out. A wire that is much too thin would even melt away immediately.

Extra thick battery cables can also be found in the plus circuit between the alternator, the starter motor and the battery PLUS pole. Here also very large currents go through, so a thin wire will not suffice.

Ideally, you should use at least 20 mm², but that also depends entirely on the application. It may also be necessary to use much thicker cables.

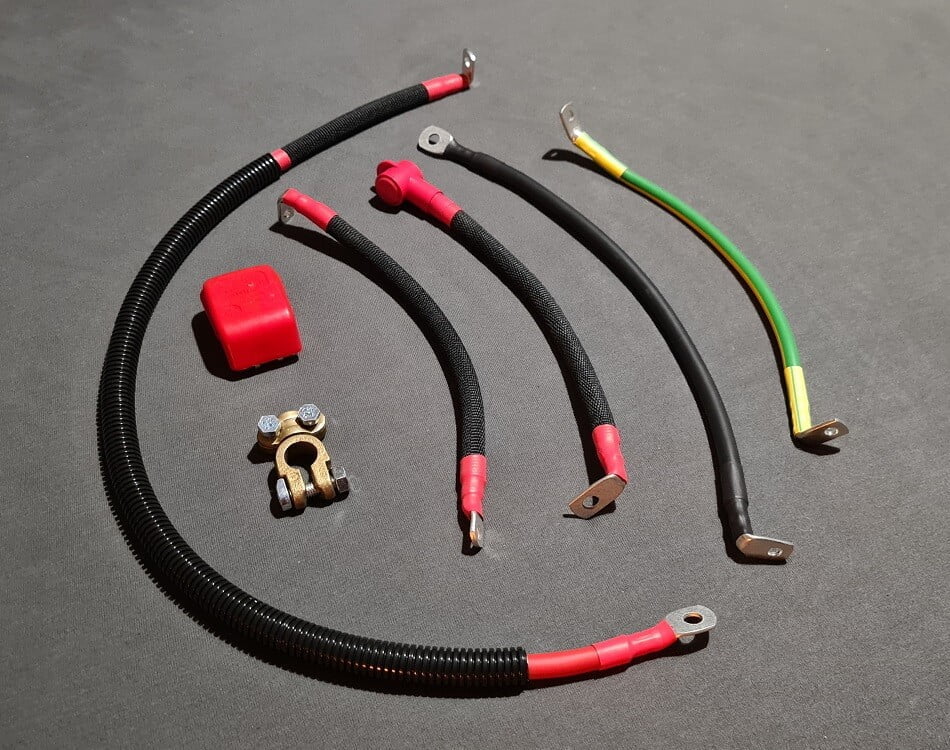

Below you can see examples of some 25 mm² and 35 mm² battery cables that we customize.

Upgrading your old worn out battery cables

We often see that especially in older cars very thin battery cables were used. Like 10 mm² or even only 6 mm². You then get charging problems with the current batteries.

Nowadays it is recommended to use thick cables of 16 mm² or 25 mm². In some situations, such as classic vehicles that have a 6 Volt battery, even thicker cables such as 35 mm² are required due to the larger currents. In the audio scene, where they drive speakers and subwoofers that draw very large currents, even thicker cables are used.

Thicker battery cables are a very good asset in your (classic) car. This is the base of your electrical circuit. If you already have voltage loss here due to bad, thin or worn cables then all the other work is just mopping up. Think of it as renovating a house, but the foundation is rotten. That's not going to work.

Worn down battery cables can cause all kinds of nasty electrical problems in your car. For example, lights that run at half power, a horn that makes little or no sound, slow running wipers, fans that run at half power, the battery that no longer charges enough to stop you when you have your lights or heater fan on, problems with the fuel supply or ignition, etc.

Because many people have little knowledge of electricity, unnecessary emergency solutions are often thought up, such as pulling all kinds of extra (ground) cables. This is a great pity because, apart from the fact that it creates unsafe situations, the connections are often not reliable either and unnecessary cables are drawn in places where the root of the problem is not located at all. And all those superfluous wires do not look neat either. Ever been to Thailand? They do the same there. If there is a problem, they just pull an extra wire instead of solving it.

Okay, so thick battery cables are important in the electrical circuit of your car. However, it is not necessary to overdo it. If 25mm² is more than sufficient, there is no reason to mount for example 50mm². This will only increase the weight, the cost and the profit you will make with it is negligible.

"We make completely new extra thick battery cable sets for all vehicles as a replacement for the existing battery cables"

We can replace the battery cables for all vehicles for a nice new set of for example 25 mm² thick battery cables. In 6 Volt installations we use 35 mm² because there are larger currents. These cables are extra well finished and insulated which gives them a nice tight look and makes them last very long without problems. In the automotive industry such a battery cable upgrade is also known as The BIG 3 or BIG 4 upgrade. For my own car, the Peugeot 205, there are even 5 battery cables and that is why we call it the Peugeot 205 the BIG 5 battery cable set upgrade.

Voltage drop in the electrical circuit of your car

Now that you understand the basics a bit better, I will go into more detail about voltage drop and what causes it and what you can do about it.

In the most ideal situation, there is no resistance whatsoever on the way to a consumer in the electrical circuit and back to the voltage source. In that case, the current can flow freely and there is no voltage drop. You will then have the highest possible efficiency. This means that when your voltage source gives 12.6 Volt while the light bulb is on, we also measure this 12.6 Volt at the light bulb.

So what happens when we do experience voltage drop in our electrical circuit?

Resistance explained with an example

When we experience voltage drop, there is resistance somewhere in the electrical circuit. To make things clearer, let me explain this with an example.

For example, think of a river with flowing water. Somewhere in the river is a paddle wheel. The paddle wheel can be compared to a car lamp. Water flows through the river and makes the wheel turn. In the example of the lamp in the car, the lamp will light up due to the flow of electrical energy.

When we now place a large stone in the stream it is a resistance. It obstructs the optimal flow of the running water. The bigger we make the stone or the more stones we add (more resistance) the less flowing water can run and the less pressure / tension remains to make the wheel turn. In the car the lamp will burn less brightly and in the stream the paddle-wheel will turn less fast. These stones that give resistance in the stream can be compared with transition resistance by for example corrosion in the electrical circuit of your car.

What forms of resistance are known in (classic) cars and other vehicles?

Resistors in an electrical circuit come in various forms. Below I will explain the most important ones you may encounter in your (classic) car or other vehicle. We know contact resistancebut also the wire thickness and wire length are factors that play a role in the resistance of the electrical circuit.

Transition resistance due to corrosion

The most common resistance in vehicles comes from corrosion. Corrosion is actually a general term that occurs with all metals when they are exposed to oxygen and moisture. Then a chemical process takes place that we call oxidation. With iron metals you know this in the form of rust. The iron is eventually affected and literally eaten by the oxidation process.

In the electrical circuit of your car, this oxidation causes transition resistance. The corrosion originates at the exposed metal parts that have to carry the current from one metal to another. In the electrical circuit of your older car or motorcycle, corrosion can often be found on the Earth points on the body and the wiring in plugs. You can tell by the green colour.

The main disadvantage of corrosion is that it can cause very high transition resistance. This means that the current will no longer be passed on properly between the contacts of the cable lugs or the body. The voltage will, as it were, drop over the corrosion. In the example of the stream, the pressure of the water will fall over the stone. In severe cases this can cause your lights or other electrical components such as sensors or your starter motor to malfunction or not work at all. Just like the paddle wheel will stop turning when the current is limited too much by the resistance of the stones. All the pressure then falls away over the stones and does not reach the consumer/load anymore.

What can we do about corrosion?

Do you unplug a connector and does it look all green and dirty inside? Then clean it with a (tooth)brush Or cloth and some contact spray. You can also use brake cleaner to clean the plastic connector. To get the cable terminals shiny again you can use contact spray and use a brush or if it's really bad use a small dremel. Contact spray works well to remove the metal to polish and also works preventively against the formation of corrosion. The starting point is to see nice clean bare metal again.

Replacement of cable lugs and eyelets

If the lugs are damaged too much it is best to replace them with new ones. You will need the right tools for this, such as the right crimping pliers / cable shoe pliers and stripping pliers.

You can also polish a cable lug with a dremeltje and some contact spray. It is better to just place a new eye. Never use a vice or water pump pliers to fix the connectors and eyelets in an amateurish way. This does not only look bad, it also does not provide a safe and long term reliable connection.

If you have a wire with an eyelet that connects to the body. Don't forget to clean the side where the eye is attached to. This can be the bodywork for example. Also clean any washers, bolts and nuts that are in direct contact with the metal eye. Preferably just use new bolts and nuts if possible. Preferably stainless steel because they do not rust.

In any situation, you should always have a connection of bright shiny metal to bright shiny metal want to have. All dirt, grease, rust, corrosion, etc. is resistance and causes voltage drop.

Shrink tubing advantages

When replacing cable lugs and eyelets, it is advisable to put heat shrink tubing over the connection between the copper wire and the cable lugs. This has 3 major advantages.

- Firstly, it prevents corrosion to a large extent.

- In an older car, you often see cable lugs that are only attached with 1 copper wire. Shrink tubing gives extra strength so you won't have this problem anymore.

- Finally, it helps to prevent short circuits.

Vaseline

Last, but certainly not least, we can recommend you to go to the ground connection points on the body and the cable lugs in plugs what vaseline lubrication. Especially in the wet parts like under the hood. This way no air and moisture can get to the metal. no chance of corrosion gets.

Resistance due to too thin wires

When connecting electrics in your car, it is important to take into account the wire thickness. The factory usually chooses wires that are barely sufficient. This has to do with economical reasons. There are so many wires running through a car that this increases the production costs enormously. There can be hundreds of meters or even kilometers of wire in your car, and copper wire is expensive. That's why the manufacturers are looking for an optimal balance in which the costs are kept as low as possible and where there is not too much voltage loss over the wires. 10% voltage drop is allowed. That's how everything works when it's new but it also has some drawbacks, especially after a longer period of time.

The disadvantages of thin wires

These thin wires have trouble dealing with the large currents, so they not only cause resistance and thus voltage loss, but they also heat up over the years, causing them to wear and discolour. This changes the specific resistance of the copper, resulting in even more voltage drop.

Why do they do this? Simple, as I mentioned before they choose for an optimal balance to get everything working and keep the costs as low as possible. Also, for a manufacturer, a car doesn't have to work for more than 10 years.

You can imagine that when you drive a car for a longer period of time, this wear and tear will eventually take its toll. Especially with wires that carry a lot of current, such as fog lights, fans and headlights, you can see that the wires are completely discolored. If you then look at the wire of a parking light, these are often still nice and shiny copper. This is because such a city light of a few watts requires little power. That wire is usually a little thinner but more than thick enough for the small current. The headlight wire is usually made a fraction thicker but still has a lot to endure because of the constantly high current that runs through it.

Resistance by the length of wires

Finally, besides the thickness of the wire also the length of the wire. The thickness is also dependent on the length of the wire. The longer a wire the more resistance it has. Actually quite logical because the current must travel a longer distance and therefore suffers from more friction. Therefore, the longer a wire is the thicker it needs to be.

You might have noticed this in practice when you tried to charge your phone with a long USB cable of 2 or 3 meters. Usually this just doesn't work and it can take up to 5 or 6 hours before your phone is full. If you use your phone at the same time it will probably not charge at all. You are actually using up all the energy that is coming in without having anything left to charge the battery.

Why is that? Simple, they can use longer wires, but if they don't also make them thicker, the wires will have too much resistance. Eventually there will be very little voltage left at the side of your phone because the voltage will fall over the resistance of the wire. A good USB cable that can handle that length will be a lot thicker and more expensive. That is why thick battery cables are so nice, because they will charge your battery much better and fuller.

Good, too thin wires is also an example of resistance in your electrical circuit. In principle you can go ahead with the wires from the factory, but then there shouldn't be any extra resistance in the circuit anymore. Otherwise it becomes a sum.

After all, you already lose a bit of voltage over the wires from the factory, and that is why it is all the more important that your electrical circuit is in a good condition. It is therefore advisable to at least upgrade your battery cables to a larger thickness such as 25mm². That is always a good investment because it gives you a good basis.

What disturbances can be expected due to transient resistance?

Okay, now it's clear to you that your electrical circuit has to be free of transition resistance. If it isn't, you're likely to get all kinds of nasty electrical problems. Here's a short list of common failures caused by transient resistance:

- Weak or failing lighting

- Bad audible horn

- Slow Moving Wipers

- Poor or no starting ability

- Battery not charging enough

- Bad running motor

- Fuel pump failure

- Bad ignition

- Faulty or interfering meters and alarm lights

- Fans that no longer run powerfully

- Consumers working sporadically and unreliably

- Flashing lights

- And much more

Strange malfunctions due to bad ground

There's one more weird glitch you might have encountered. It's like being dropped at the fairground. In that case there is such a bad ground that the current will find its way through other consumers. Let me explain.

Suppose your blinker has no or very bad ground. When you turn on your blinker, the current will find its way back to the MIN pole of the battery. This can cause the current to flow through other devices which are not connected at that moment. But as you can imagine, if the current goes through other electrical components back to the battery, they will start blinking as well. It could be that you suddenly get blinking rear lights or blinking gauges in your instrument panel, like your fuel gauge that suddenly starts dancing on the rhythm of your blinkers. Maybe funny for once but of course not desirable.

When you have such a malfunction, make sure you check the ground connection of the electrical consumer that causes it. In the case of the example, check the ground connection of the indicators.

Summary of contact resistance and voltage drop

In almost all cars and other vehicles that are getting older, you will eventually have to deal with resistance in the electrical circuit. This is mainly caused by transition resistance in the form of corrosion. This resistance is mainly found at ground connection points and on cable lugs in plug connections in damp areas such as under the bonnet.

This transition resistance causes voltage loss and can cause very annoying malfunctions, such as components that operate at half power, lamps that no longer shine brightly, a horn that no longer makes any sound, dashboard gauges that interfere or do not indicate anything, poor engine running or starting problems.

From the factory, there are actually factors that cause resistance and thus voltage loss in the electrical circuit of your car. This is because manufacturers choose to use the thinnest wires possible to keep production costs low. They have made sure that everything works well for about 10 years, provided that proper maintenance is done. Many people like to drive their car for a longer period of time and in that case you will have to take measures to counteract the additional voltage loss that will occur.

You can do this by removing any transition resistance such as corrosion. In connectors you can use a brush with some contact spray to do this. Brake cleaner also works well to clean the whole thing. On ground connection points, you can give it a good clean with a cloth or use a small dremel.

It is even better to use new cable lugs and replace old rusty bolts and nuts with new stainless steel ones. The starting point is always to get a connection from shiny bare metal to shiny bare metal.

In really old classics and old timers, wires and cables are often no longer usable at all. They are so worn out that they hardly conduct electricity at all. Conductors are broken and the insulation is completely dissolved or hardened. You can often see the insulation and wires just pulverize when you touch them. Replacement is then highly recommended.

See below for some examples of pulverized insulation.

The wiring harness wear is a sum of all kinds of influences. First of all, there is the lifespan, of course. Over the years the wires are exposed to electric current and the surrounding insulation to moisture, heat, cold and liquids like oil and coolant. Eventually it just runs out and you need a new one. wiring harness in your classic car needed.

If you are interested in a complete new harness for your oldtimer (Traction Avant is our specialisation) or restoration and repair of the harness of your youngtimer. Or are you looking for a new battery cable set for your vehicle. We can help you further.

Then take here contact us for the possibilities.

2 responses

Hello Ihr Lieben!

Tolle Webseite! Chapeau! Ich habe euch beim Googeln gefunden und habe tatsächlich einen Citroën 11 CV Normale von 1953 im Oktober 2024 erworben. Seitdem das schöne Auto nicht mehr in der Schweiz, sondern bei mir am Niederrhein fährt, springt er regelmäßig nicht mehr an. Und dann manchmal, wenn ich an den Kabeln rüttele, plötzlich - aber selten - springt die Traction Avant wieder wie eine junge Göttin an. Wenn sie nicht starten will, bockt auch mal die Hupe oder die Scheinwerfer fallen aus. Und kurz darauf geht das wieder, aber kein Starten. Ein langsames müdes Drehen des Anlassers. Da der Schweizer Vorbesitzer ganz viel neu gemacht hat, wundere ich mich über dieses Verhalten der alten Dame.

Wenn Ihr Spezialisten der Traction Avan seid, habt Ihr vielleicht einen Plan der Elektrik dieses Autos?

Ich gucke morgen auch schon mal nach, ob der Kabelbaum ausgetauscht wurde. Was kostet denn so ein gutes Stück bei Euch?

Was ist euer Rat?

Liebe Grüße, Matthias

Hello Matthias,

Congratulations on the purchase of your Traction.

All the problems you mention are more than familiar to us and is exactly what we solve in the Traction.

The wiring is the problem. Wear and tear, wire breaks and corrosion will give you these problems. Also because ground connections were very poor in those days. That's why shaking sometimes works.

We make the wiring for the whole car new. We will send you an email for further contact.

Kind regards,

Jesper